Bainbridge Chemical Corporation

Bainbridge Chemical Corporation

1300 Spring Creek Rd

Bainbridge, Georgia, USA 39817

Plant Phone: (229) 246-4552

Plant Fax: (229) 246-3245

Sales Order Phone: (229) 244-0000

President

Marty McGhin: marty@georgiagulfsulfur.com

Customer Service RepresentativeShirley Lusk: shirley@georgiagulfsulfur.com

Company History

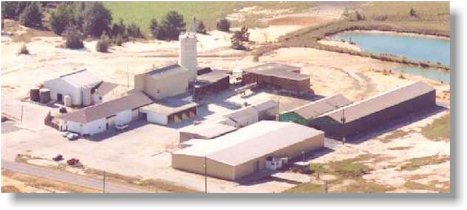

The Georgia Gulf Sulfur manufacturing plant, in Bainbridge Georgia, was conceived and built in the late 1950's to expand Mr. R.A. Griffin's seed and chemical formulation business into the manufacture of sulfur fungicides and miticides. A plant site was purchased on Spring Creek Road, adjacent to the Texas Gulf Sulfur storage facility, at Georgia's inland port facility, on the Flint River. Production commenced in 1959 using dry bulk sulfur from the Texas Gulf Sulfur terminal. Sulfur supply was changed to molten sulfur in 1974. In 1983 a fluid sulfur production unit was added to the site, currently operating as Bainbridge Chemical Corporation.

Travel Directions

From Interstate 10 - Tallahassee, FL

Exit onto U.S. 27 North from Tallahassee, Florida. When reaching Bainbridge, Georgia at the junction of U.S. 27 and U.S. 84, turn left onto U.S. 27 North / U.S. 84 West. Proceed to the first exit past the Flint River crossing and exit on State Road 253 / Spring Creek Road. Turn left and proceed one mile. Georgia Gulf Sulfur Corporation and Bainbridge Chemical Corporation are located on the right.

From Interstate 75 - Valdosta, GA

Exit west on U.S. 84 Valdosta, Georgia. Proceed west 82 miles to Bainbridge, Georgia. Turn left on U.S. 84 West Bypass on the east side of Bainbridge. Proceed to the first exit past the Flint River crossing and exit at State Road 253 / Spring Creek Road. Turn left and proceed on State Road 253 one mile. Georgia Gulf Sulfur Corporation and Bainbridge Chemical Corporation are located on the right.

| Technical Product Data - Bainbridge Chemical Corporation | |||||||

|---|---|---|---|---|---|---|---|

| Product Name | Assay or Purity | Ash | Acidity | Heat Loss or Moisture | Processing Oil | Other Additives | Fineness - % through US screens |

| Rubber Maker's Sulfur | |||||||

| GGS-10 | 99.5% min | 0.10% max | 0.01% max | 0.15% max | - | - | 100 Mesh - 99.5% min 200 Mesh - 90% to 96% |

| GGS-11 | 99.5% min | 0.10% max | 0.01% ma | 0.15% max | - | - | 200 Mesh - 98% min |

| GGS-20 | 99.0% min | 0.10% max | 0.01% max | 0.15% max | 0.35% to .50% | - | 100 Mesh - 99.5% min 200 Mesh - 90% to 96% |

| GGS-33 | 99.5% min | 0.10% max | 0.01% max | 0.15% max | - | - | 100 Mesh - 99.5% min 325 Mesh - 95% min |

| GGS-35 | 98.75% min | 0.35% max | 0.01% max | 0.15% max | 0.75% max | 0.25% max | 100 Mesh - 99.5% min 325 Mesh - 90% to 95% |

| GGS-40 | 99.5% min | 0.10% max | 0.01% max | 0.15% max | - | - | 80 Mesh - 90% min |

| MCO 2.5 | 97.0% min | 2.5% max | 0.01% max | 0.15% max | .50% max | 2.0% max | 200 Mesh - 99% min 325 Mesh - 90% to 95% |

| MC HOT | 96.4% min | 2.6% max | 0.01% max | 0.15% max | 1.0% max | 2.5% max | 200 Mesh - 99% min 325 Mesh - 90% to 95% |

| MC 98 | 97.5% min | 2.1% max | 0.01% max | 0.15% max | - | 2.0% max | 100 Mesh - 99.9% min 325 Mesh - 98% min |

| Industrial Sulfur | |||||||

| Code 803R | 99.5% min | 0.10% max | 0.01% max | 0.15% max | - | - | 200 Mesh - 60% to 80% |

| Drum Flake | 99.5% min | 0.10% max | 0.01% max | 0.15% max | - | - | 1/2" Mesh - 95.0% min |

| Code 420 | 9.5% min | 0.10% max | 0.01% max | 0.15% max | - | - | 4 Mesh - 99.5% min 20 Mesh - 5.0% max |

| Pastille | 99.5% min | 0.10% max | 0.01% max | 0.10% max | - | - | 4 Mesh - 98.0% min 100 Mesh - 2.0% max |

| 70% Emulsified | 69% to 72% | - | - | - | - | 28% to 31% | less than 5 microns |

| Agricultural Sulfur | |||||||

| Wettable Dusting | 90% min | - | - | - | - | 10% max | 325 Mesh - 93% min |

| Granular | 90% min | - | - | - | - | 10% max | granules |

| Dust Free Suspension | 95% min | - | - | - | - | 5% max | 200 Mesh - 85% to 92% |

| Flowable | 53% min | - | - | - | - | 47.0% | contains 6 pounds of sulfur per gallon |